After being around for about 40 years, 3D printing found its way into many industries and applications, including jewelry making. From speeding up the casting process to creating silver and gold jewelry within a quick run, different printing methods are adapted by more professionals to their specific needs.

- Traditional ways of making Jewelry

- How 3D Printing is used for Jewelry making?

- What materials are possible

- Competitive advantages of 3D printing for jewelry

- Jewelry 3D Printing Service

- CNC vs 3D printing: what’s better for your workshop

Traditional ways of making Jewelry

To understand how 3D printing found its niche, we need to quickly touch upon regular jewelry-making methods.

For single custom pieces, many jewelers work manually by using both machine and hand tools. This tedious process strongly relies on years of experience and knowledge of a goldsmith to create a unique piece.

Some companies rely on using CNC machines for either carving wax models or cutting jewelry pieces from precious metals directly. More on that manufacturing method, we touch on a different guide here.

For mass-produced jewelry or complicated single pieces, commonly metal casting is used. Casting allows to replicate the same designs many times with perfection and speeds up the process making it possible to get several pieces done in one run.

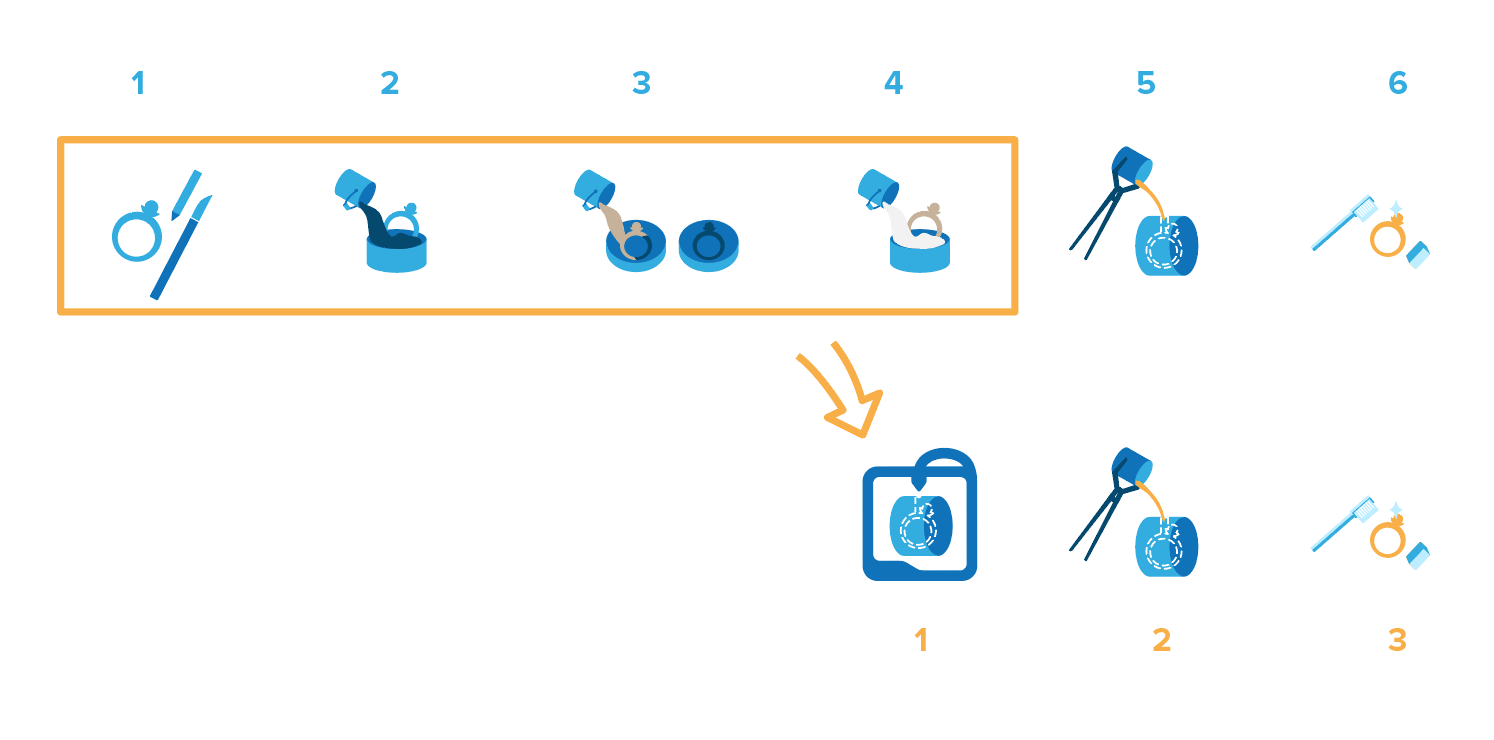

How Jewelry casting works:

- Master design (Jewelry model)

First, the master model is made. Usually, it is carved manually from modeling clay or special wax.

- Making the press form

Using the master model, a press form is created. The master model is covered with a liquid material. After it’s hardened, the object is halved. Now it is possible to create intermediate wax models for casting.

- Intermediate model

Using a special wax and press form, the intermediate model is made.

- Making the casting mold

The intermediate model is covered with gypsum to get the casting mold.

- Casting the piece

The liquified metal is poured into a gypsum mold. It replaces the wax by simply melting or burning it out.

- Post-processing

The final item is carefully taken out, mechanically handled and polished.

How 3D Printing is used for Jewelry making?

So, what does 3D printing bring to the table? Some additive manufacturing technologies allow getting a master model for casting right from a CAD model with great precision and speeds. Others allow just printing the jewelry pieces from metals right away.

3D Printing Master Models for Jewelry

Mainly, for creating master patterns resin curing methods are used thanks to their accuracy and ability to transfer really delicate and smooth details. These include DLP, DUP, 3DP, and, mainly, Stereolithography, or SLA.

The family of VAT polymerization techniques works by curing photopolymer resins layer by layer to form an object. Due to becoming more and more popular in jewelry and metal casting, these 3D printing methods have specifically formulated casting resins. The end product is very similar to jewelry wax and burns cleanly from a cast.

Among the main competitive advantages of using resin printers are time-saving. You just open a 3D model, add supports and send it to the machine. Additionally, SLA and DLP 3D printers use laser/light projections that can form tiny elements which range from difficult to impossible to achieve manually. To top it off, customers can review 3D printed prototypes and request changes before jewelers manufacture the final product.

3D printing Metal Jewelry

Some AM technologies allow printing with metals directly from a CAD design. The most widely spread technologies for such use are DMLS and SLM. While prime metal powders they work with are aluminum and steel, some machines can handle precious alloys, too.

SLM and DMLS 3D printing work by melting fine grains of metallic powder with a laser. Working layer by layer, it creates solid metal parts. The common downside of metal 3D printing is that the strength of printed objects is lower in comparison to machined, cast, or welded parts from the same material.

Is it possible to 3D print gold?

In the latter, when an object is formed from metal powder, using gold or other precious alloys is too expensive. Furthermore, the minimal size of elements for direct metal 3D printing shouldn’t be less than 1-2 mm whereas, jewelry usually contains more intricate details.

However, 3D printing in precious metals is still practiced. For example, designer Lionel Theodore Dean made a series of golden adornments with a 3D printer for metal.

What other materials are possible?

While jewelry is commonly created from precious metals and gems, nowadays fashion Jewelry or bijouterie is popular, too. Accessories from versatile materials from plastics to natural mediums make a strong competition to fine jewelry.

3D printing can be applied to such accessories as well. It comes in handy for printing master models for cold casting (in resin jewelry). And SLS or FDM can produce plastic pieces of peculiar forms and designs.

Competitive advantages of 3D printing for jewelry

To sum it up, 3D printing makes custom jewelry much more affordable. This technology can be supplemented by the traditional methods of manufacturing that are already in use by jewelers such as CNC machining and milling.

Many customers nowadays are looking for custom pendants and rings that were made upon request rather than regular goods from the shops. And 3D printing allows jewelry entrepreneurs to make all their products on demand. Before the customer chooses an item on the site and clicks the “Order” button, the product doesn’t exist.

For the jeweler, it cuts down extra money on showrooms or expensive storage facilities. Meanwhile, the cost of SLA and DLP 3D printers capable of 3D printing in castable resins continues to become less expensive every year, whilst the quality becomes higher and higher. As a result, we see more young professionals joining the industry.

Time efficiency and wider geometry possibilities are important advantages that 3D printing brings as well. Certain intricacy and details become possible through printing, while smart implementation of AM speeds up the process and improves a jewelry workshop.

3D printing Jewelry service

Critical to note that it’s not just the machines that you need but a high-skilled operator too. In case you are not going to spend money on a new 3D printer and expand your staff, you can order a wax model or jewelry piece through Treatstock. Our new 3D printing services directory, among other options, makes searching for suitable local 3D print shops easy and convenient. If you prefer a quicker way and have a CAD design on hand, we can instantly quote for you:

CNC vs 3D printing: what’s better for your workshop

Jewelers all over the world use different methods and technologies in their work. Both CNC processing and 3D printing can be beneficial for goldsmiths. Here is a quick rundown on both:

CNC for Jewelry

- Desktop CNC machines cost less than SLA/DLP printers;

- Solid wax is cheaper than liquid polymers used in 3D printing;

- Relatively easier to learn.

3D printing for Jewelry

- More complicated shapes and geometric forms possible;

- SLA and DLP 3D printers can “grow” several wax patterns at the same time;

- Speed of manufacturing is higher.

In summary, the choice of CNC machining or 3D printing depends on what kind of product you need to create. If you need to make relatively simple shapes like rings or bracelets, CNC will suffice. Goldsmiths state that 4- axis and 5-axis machines generally can fulfill most functions of a 3D printer.

However, when one considers very small and delicate work that can only be done manually, you can use all the potential of SLA and DLP printers. And once metal powders become more affordable, we are pretty sure to see more 3D printed jewelry on the market.

Check out 3D Printable Jewelry and Accessories

If you are wondering how printed jewelry pieces turn out or look for inspiration, you can explore original designs in our product catalog here.