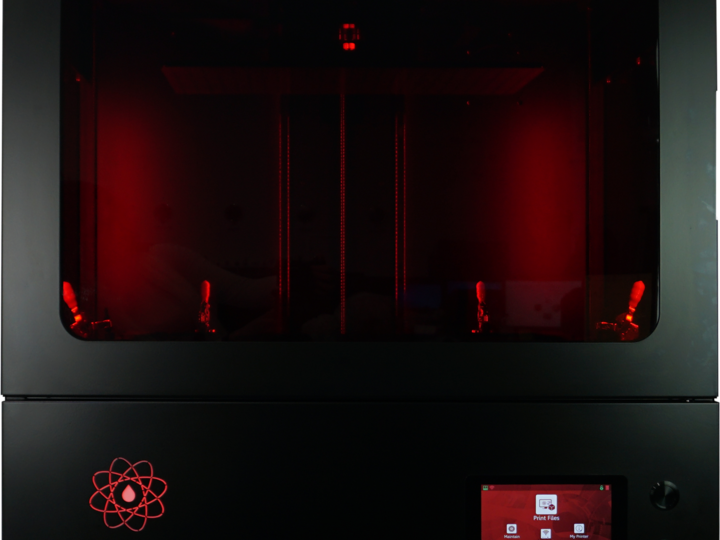

These 3D printers make objects upside down by immersing the built platform into a resin tank and lighting the areas from underneath which results in materials becoming solid layer-by-layer. They use a code to coordinate the light source and polymerize only the areas that make up an object. As a light source, DLP printers use projectors to solidify the resin. This digital screen under the tank displays the image of each layer, built from square pixels like in old computer games. DLP machines combine precision with better printing speeds. Find a suitable unit in our catalog or check out other technologies for comparison.